9. Washing gold from gravels, sands & soils – trapping the heavy grains

Grains of gold have a special property that makes them relatively easy to harvest from piles of loose granular material. They are many times heavier than the grains of the non-gold granular rocks & minerals.

- Provided that the grains are free to move vertically, the gold grains will have a tendency to descend to the lowest levels.

- In a buoyant environment, the lighter grains will tend to rise with the lightest grains ending up on top. Tiny grains of mud or clay are usually the lightest.

- Any container of water in which the mineral grains can be well agitated will achieve these conditions.

This is the core process used in washing gold.

In practice there are a couple of other processes that also need to be undertaken in order to achieve good productivity

- The first is to prepare the raw granular material for processing. It is important that the gold grains are free & not attached to other mineral material. In Wattle Flat the gold grains are often found encased in sticky red clay. The gold grains must be at least loosened from the sticky clay before they can be effectively processed by gravity gold harvesting. This can be achieved by massaging the clay by hand in a gold pan or by using a mud puddling machine. It can also be very beneficial to sieve or screen the material to be processed to eliminate, very large grains & organic material.

- The second is to effectively remove the lighter non-gold grains from above the gold, without losing any of the gold. This can be achieved by just scraping of the top layers, & /or by allowing a stream of water to wash the lighter grains away.

After these processes have taken place, the residual material should be a concentrate of heavier mineral grains including all the gold. The washing process can be repeated to further concentrate the residue or to keen up the gold grains.

Gold Panning in a creek bed- a very effective fully manual process.

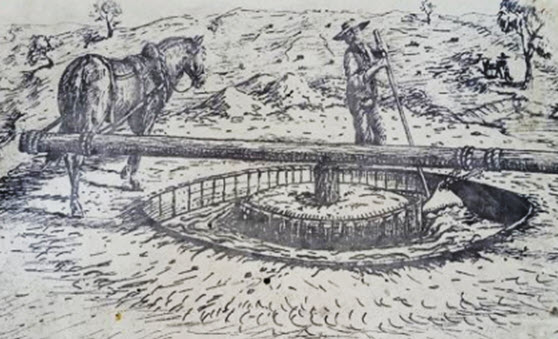

Puddling Machine for softening sticky clay prior to panning or sluicing

Rocker Box for use where insufficient water for sluicing

Sluice Box using rapid water flow over a bed of removable riffles

Through historic times, a variety of tools & machines have evolved with varying degrees of sophistication to carry out these basic gold washing processes.

For small amounts of material a gold pan has long proved to be an effective tool

The gold pan is very simple & very portable. It can be made of wood, metal or plastic. A gold pan requires skilled manual handling and access to a body of water. A series of manipulations & specific motions with a gold pan can efficiently wash gold from a few kilograms of gold bearing granular sediment or soil.

To handle larger amounts (a few tons) of gold bearing granular material it would be more efficient to use a puddling machine (if working sticky clay), & a sluice box or rocker box depending on the amount of water available.

- A Puddling Machine uses a mechanical process to massage large amounts of heavy clay material and soften it for subsequent panning, sluicing or rocking.

- Sluice boxes of all kinds & sizes need a constant stream of water to flow through them. They are essentially a channel, with a removable rough floor with a series of riffles or baffles to trap the gold which the water agitated lighter mineral grains are constantly washed through by the stream of water.

- Rocker boxes are similar to sluice boxes, but are modified for situations when there is limited flowing water available. Small amounts of water are bailed into the top of the rocker box, and agitation of the gravels & sands is enhanced by rocking the whole device.