10. Gold extraction from quartz reef rock - more sophisticated machines required

With the advent of quartz-reef mining for gold, the process of gold extraction became industrialised often using sophisticated machines & steam power.

We know that a succession of 3 stamp batteries were used here at Solitary as detailed at Station 11. The machines that were used in conjunction with the stamp batteries to process the gold bearing sands are of particular interest. These include mineral concentrators and shaking tables.

Denny’s Concentrator: One of the first men to locally develop more sophisticated engineering technology to make gold extraction more efficient & economical was Thomas Denny (1835-1895). While the owner & manager of the Denison Iron Foundry in Bathurst, he devised & manufactured machines to process battery sands at quartz reef processing mills like Solitary. His machines were designed to be more selective in separating different heavy mineral products by using combinations of grinding, vibration, sieving & sluicing. He & his company (Solitary Reef Gold Mining Company) invested heavily in developing this project between 1879 & 1884. His 1881 patent improved separator & concentrator was installed along with shaking tables, and mercury amalgamation equipment. This machine was designed to process the sands from Campbell’s 10 head stamp battery and the previously accumulated sands amounting to several thousand tons.

Image of Denny’s Patent concentrator from article published in the Australian Town & Country Journal 27th Aug 1881

Name plate from Denny’s Patent Concentrator – 1881 found in Wattle Flat.(courtesy of Lloyd Breckenridge)

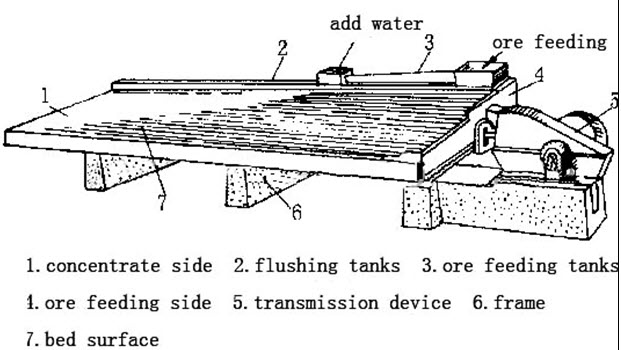

Shaking tables were a very important and sophisticated machine used to process the sands delivered from the stamp batteries at quartz-reef milling sites like Solitary.

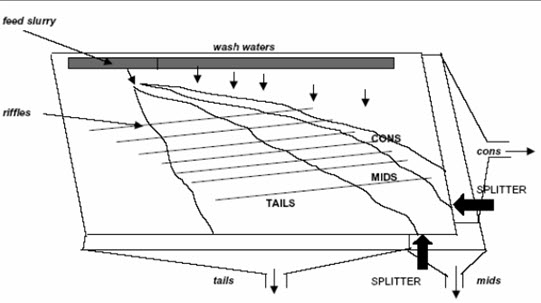

Basically a shaking table is a flat table with a set of longitudinal parallel riffles. The table top can be subtly tilted both longitudinally & laterally. The table is designed to oscillate 1-3cm in the longitudinal plane 200-300 times per minute. A mineral bearing slurry is introduced in the feed corner of the table, and additional washing water causes this to flow as a thin film across the surface of the table to a set of collection troughs on the other side of the table. A combination of the variable table tilt, water flow rate, and oscillation (amplitude & frequency) causes mineral grains of different densities to report to different collection troughs. Through experimentation the table can be set to separate the different mineral types for any given situation.

Here at Solitary shaking tables would have been used to separate 3 mineral streams: (1) free gold; (2) sulphide concentrate and; (3) barren quartz & wall rock.

Stamp Battery below which a shaking table would be installed

Shaking Table using gentle water flow and vibration to separate streams of heavy from lighter mineral grains

Plan view of shaking table showing flow paths from feed slurry to 3 streams ( Tails-light minerals), Mids, & Cons (heavy concentrate eg. gold)